- The technician will ensure the vehicle is safely positioned and is OFF before exiting the vehicle.

- The technician will identify himself to the contact person at the site and obtain a safe-work permit.

- A tail-gate meeting will be held with all concerned parties to explain the test procedure and gain specific site information.

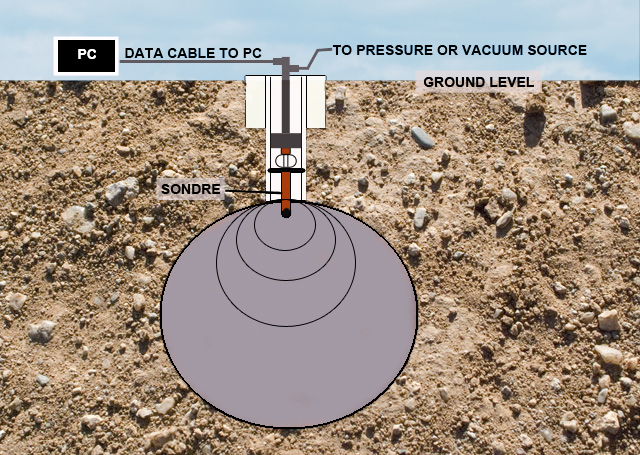

- This procedure is an electronically controlled system. The process uses an acoustic transducer, which collects data from inside the vessel.

- The transducer is inserted into an empty vessel and the entrances are then sealed.

- Once the transducer is inserted and the system sealed, a background noise reference is recorded.

- Pressure is introduced into the system (nitrogen). The test pressure is determined by the depth of the tank.

- The program then runs a test comparison on the background already achieved and the noise ratio after the nitrogen is introduced.

- The digital leak test data is collected to determine if the Ullage portion of the tank passed or failed.

- The process has been EPA third party certified to the non-volumetric protocol.

- We guarantee an accurate cost-effective result to your D-55 regulatory compliance testing.

- At the conclusion of the test, the technician will remove all test equipment and return the safe work permit to the originator or their designate.

- The vessel may then be returned to normal service or remedial action taken.

- A written report will be provided.

Reviewed Oct 31/16

Typical Acoustic Test: